A warehouse supplies a central location which allows welcoming, to store and to distribute products. As every entering sending arrives, the responsibility of the transfers of goods to the staff of the warehouse, products are identified, sorted out and sent in their temporary storage place. The storage is not a static “thing”, but rather a process which includes security measures and environment which protects the integrity and the utility of objects. When it’s time to move objects, every order is getting backed, grouped, packed and verified for the exhaustiveness before being sent to their new destination.

The different steps of Warehousing

The storing and the management of warehouses represent a very important part in the management system of the logistics, which is itself an element of the management of the supply chain. We define this part as a simple place which serves in, on one side, to store finished products, followed by the entrances functions which prepare elements for the storage and on the other hand are the outgoing functions which strengthen, pack and deliver orders. These two gathered stages supply economic advantages and important services both for the company and for its customers.

DocShipper Advice : In order to optimize our services, Siam Shipping and Siam Relocation are now part of the DocShipper group. Our customers can now benefit from total supply chain coverage.

In situations where it is more cost-effective, we maintain excellent relations with numerous trucking services to move your shipment anywhere across Asia.

Operation of valuable addition

There are various objectives in a system of logistics. The main objective is to reduce the times of cycle and the global inventories, to reduce the costs and, especially, to improve the customer service. The storing increases the value of the utility of the goods by supplying a way to have the good available products at the right place, and especially, at the right time. The operations such as the consolidation of orders, the assembly of orders, the mixture of products and the spacer which take place in the structure of the warehouse also add an added value to the global logistic system.

Economic profits

Warehouses allow obtaining economies of scale thanks to effective operations, to storage capacity and to a central location. The economic advantages are realized, for example, by operations of consolidation and accumulation. The operations of consolidation reduce the costs of delivery at the same time for the company and its customers. Instead of sending articles individually from multiple springs, articles are delivered in a central warehouse, packed together and sent as a complete command. The operations of accumulation allow a warehouse to act as a stamp, balancing the supply and demand for the seasonal and long-term storage. It can be vital for the profitability of the company when the request for a product is all year, but the product can be available only in precise periods of the year.

Advantages of this process

Advantages of the service warehouses can serve within the framework of an emergency plan to make sure that the outgoing orders are entirely and in time. A called practice safety stock allows the companies to maintain a number predetermined of articles of inventory in their warehouse. On the entering side, the storage of safety means that an urgency such as a delay of transport or a sending containing defective or damaged products will not delay the order of filling and delivery of the customers. On the outgoing side, the safety stock is an insurance against elements except stock.

DocShipper info : You can have a look on “ Holding Steady: Top 20 3PL Warehouses 2016 ” article to get an idea about who are the main player on warehousing market.

How to manage your warehouse with Smooth Operations in 10 Tips ?

In the following article you will find 10 tips to organize your warehouse to spare time and operate without difficulties.

DocShipper Tip : To be as efficient as possible, you have to do the least possible moves. You have to thing as if you were in a shop, nothing is left to chance. It is important to group products together.

-

The key is organization

It is a real time-saving to have an organized warehouse. If not, it will take a long time to the pickers to find products that would be wrong located. It is a huge waste of time. A system organizing your products in a logical and defined order has to be established.

-

First, check rightly the products coming

Verify and inspect your products as soon as they arrive in your warehouse. Note products that are damaged or any shortages. It is also very wrong to take away your products without writing it down. We could thing that products are still available whereas they are not.

-

Require common sense to organize your warehouse

No matter the size of your warehouse, having an organized system will always be an important time-saving but above all real savings. Thanks to an organized warehouse, you will be able to control your time better with pick lists.

When you have few orders with large quantities of goods. With the list, the picker should be able to take the products successively without going back each time.

When you have many little orders, a pick list in groups should be created and then when the verification stage is reached, the materials should be divided by customer.

-

Reorganization is necessary

Your business can evolve and so the organization of your warehouse won’t be efficient anymore. That is why you have to rethink your shelves and your system often to be as efficient as possible all the time.

To illustrate that, think about a product that sell well so you have many in your warehouse but the following month it is the product next to it that is high demand, you have to change the organization. In fact, the location of your materials change with supply and demand.

-

Quality control is needed

Before packing and processing, the material must be checked when they arrive in your shipping station. Items can’t be double checked each time by packers. Any items damaged has to be sent back immediately. It can be a real mess if you have a large section of deficient products, but above all you will think you have products in stocks, whereas they are damage and so unsaleable.

-

Security is important

It is important to maintain a safe environment to work with complete peace of mind. Some measures have to be taken and it is necessary to protect your employees. Because of an accident you can lose the skilled labor you needed in order to keep an operate warehouse.

An area where a forklift truck operates often require a special attention. Your operators have to be really professional and traffic lanes has to be designated to more efficiency and safety.

-

A bright warehouse is important

A safer work environment is provided by a brighter warehouse and your employees’ ability to do their job is improved. With brighter lights, you are more easily aware of what should be improved or done.

-

A training staff

Because you need to reorganize your warehouse, you also have to train your employees (whether seasoned or new). You have to take time to train a retrain them anytime it is needed. Train your staff to multitask to gain efficiency. Indeed, it will able to take the job of an employee who is not able to work.

-

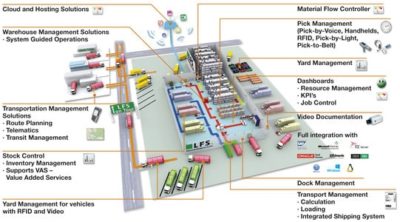

Use the right software

For material handling and warehouse you will require a large number of choices. For inventory control, labor, equipment maintenance, shipping and more, you can use programs. It is important to take the right program; providers can help you thanks to free trials. You won’t necessary need a full package, you need to find the individual programs that fit with your company.

-

Ensure prompt delivery and customer service

No matter the way of transport you use, if it is your own company that handle it or a forwarding agent, a shipment-tracking program is needed. You and your clients, have to be able to track your product and to know exactly where it is. It is important to be able to have the information to gain your clients trust.

DocShipper info : You can also have a look on the international reference for warehousing management : Amazon. Click here to visit Amazon website.

Interested in our services? Need personalized information?

Our experts will answer you within 24 hours

How to look for in a Warehouse Management System in 9 Qualities?

All warehouse management solutions are not created equal

Nowadays, WMS seems to be up to date. In an ERP solution, you include embedded WMS “modules”, the goal is to improve breed bolt-on WMS systems. Some cloud based system are even completely separate to business system. It is so hard to know the direction. You have to find the right WMS to maximize customer service and satisfaction. How to do so?

The more your customers are satisfied, to more sales and so profit you will make.

*Let’s see 9 qualities necessary for a good warehouse management system.

1) Maximum Functionality

No surprise, you have to understand first how the WMS system will help you.

You need to know if this WMS will be efficient for your business processes. For example, measuring employees’ productivity can be difficult, a good WMS can help. In this case, the WMS should be able to identify the work of an employee and where he was located, to see how efficient is your workforce.

Many different WMS are effective to help you to improve your efficiency with fewer resources. You will see if a WMS is good for you when the things it can do for you are maximized and the work on your end are minimized.

So, a good WMS should do more with less.

2) Ease of Use

An easy to use WMS is important because you will gain time on employee training, for pickers but also senior management. Users spend less time setting up and monitoring daily operations with a well-designed WMS. Thanks to that, new requirements are easy to use. It is also an important time-saving concerning new employees that will learn in hours and not in weeks how it works. The WMS functionality could this way be exploit at best by all employees.

You have also to look at the menus and help screen, see how it works, if it is easy to use because it will also improve your profitability. For instance, simplified data entry and creation of template reports and charts should be allowed by the WMS. You also need a automatically updated dashboard view to provide users an access to all of their most critical data.

So, is it easy to use this potential Warehouse Management System?

3) Complete Transaction Management

From door to door, from receiving to manifesting, you will be able to manage everything with a good WMS.

Information is king. You need to have detailed information about your products, your employees, transactions, every stage of the operations.

At least you need information at the following steps:

- Receiving

- Putting away received goods

- Order picking

- Shipping

- Cycle counting (inventory audits)

- Any item movement

With all the detailed information about how works your warehouse (people, movement, products), you will be able to choose wisely your employees and the way to stock products.

DocShipper Alert : To resume, you have to wonder if this WMS give you all the information need to track and manage all your resources.

4) Flexibility

As we saw, your business will evolve and so your WMS solution has to adapt when your company is growing or when you have new requirements. If it doesn’t, it will be fast obsolete.

How to know if it can adapt easily? One important thing is that your WMS should be able to work with the majority of ERPs. You may wonder why. In fact, when your business will grow, you will certainly have to change ERP system, that is why it is really important. Then, if your WMS is built around an open architecture, future applications and operating system are more likely to work with the WMS.

After software, you need to think of hardware. Your WMS has to be able to work with different versions of:

- RF scanners/terminals

- fork truck-mounted RF terminals

- label printers

- scales

One more thing, is your potential WMS flexible with different business types and sizes? To be sure of the flexibility of your WMS you can check if it works well with wholesale and industrial distributors of all sizes.

DocShipper Tip : To conclude, flexibility is needed because your WMS have to adapt with the growth of your business and the services that go with: many ERPs, hardware brands and types, and business models and sizes.

5) Useful, Easy-to-read Metrics

If data is important, data presentation is just as much important. Metrics allow you to track performance of your warehouse operations but it us better when you understand the data. That is why you need an easy-to-read metrics.

Thanks to a good WMS, you can easily create reports and charts and have an overview of how your warehouse is running. You will be able to analyze the performance of your employees and compare different set: morning pickers, evening pickers… Speed and accuracy are two thing needed to be performant.

That is why you may wonder if thanks to the WMS you will be able to understand the metrics and see how to improve your performance thanks to these metrics.

6) Seamless ERP Integration

To have a running business, it is necessary that your WMS and your ERP work together. As we said, the importance of a WMS that is adaptable with many ERP systems is not negligible.

*One more thing, be sure that the WMS vendor is able to develop additional ERP integrations.

7) Proven Track Record

How to be more sure that a WMS works than asking customers? Ask the vendor for a list of customer references. The customer should tell you how the system performs and if it meets their expectations. What kind of customer support did they use, how can you rate it? Does the vendor stay in touch?

You need to see multiple customer sites and try to understand how it works, keep in mind that it can be specific to the company your visit and you don’t necessary have the same needs. The best is to visit alone with the customer without salesperson.

8) Value for ROI

When you calculate your costs, keep in mind that the price is just a small part of your costs. The qualities we saw before: functionality, integration, scalability, ease of use, customer support need to be taken into account. Upfront costs are most attractive at first time but think in the long term and you can lose more at the end if your needs are not satisfied or if your WMS solution cannot support your business when it will grow and develop.

At the end, if you are mistaken in your choice of warehouse management system, you will pay far more than you will spare money to improve your WMS when your business will grow. You really have to wonder if it worth it to by a less expensive WMS if after you have to change it once your business evolves.

9) Commitment to Warehousing and Logistics

The vendor ‘s overall focus on warehousing and logistics may be a final indicator. Companies that offer business solution tools spanning many industries and requirements often deliver WMS systems. As a result, offerings in those companies are diversified but their day-to-day insight is also restricted into very specific, niche field of warehouse management. A bold-on WMS solution could be considered as a good investment (indeed you can often get them for free when you pay for an ERP system), but you only get what you pay for.

However, how can you be sure that your WMS vendor is specialize in warehousing?

You have to ask you some questions: do the vendor frequently, consistently and extensively upgrade its WMS? Are they considering customer feedback? Do they evolve as fast as the market change? Are they offering upgrades and updates for free?

There is principal things a good WMS has to do: receiving and order picking but not only. A good WMS solution has to be also good at handling comprehensive solutions (like manifesting, paperless picking across multiple zones, truck route/stop management or exotic lot number control.

——

So, you will save time and money thanks to the right WMS system and ultimately increase your customers’ satisfaction. However, if you choose the wrong WMS, it could have a very bad impact on your customer service and reputation and so on your productivity, which will represent a high cost.

To choose the right WMS you finally have to ask you the right questions.

DocShipper info: Do you like our article today? For your business interest, you may like the following useful articles :

DocShipper Advise : We help you with the entire sourcing process so don't hesitate to contact us if you have any questions!

- Having trouble finding the appropriate product? Enjoy our sourcing services, we directly find the right suppliers for you!

- You don't trust your supplier? Ask our experts to do quality control to guarantee the condition of your goods!

- Do you need help with the logistics? Our international freight department supports you with door to door services!

- You don't want to handle distribution? Our 3PL department will handle the storage, order fulfillment, and last-mile delivery!

SIAM Shipping | Procurement - Quality control - Logistics

Alibaba, Dhgate, made-in-china... Many know of websites to get supplies in Asia, but how many have come across a scam ?! It is very risky to pay an Asian supplier halfway around the world based only on promises! DocShipper offers you complete procurement services integrating logistics needs: purchasing, quality control, customization, licensing, transport...

Communication is important, which is why we strive to discuss in the most suitable way for you!